A hundred years ago, when battery cases were made of porous materials, such as wood, storing batteries on concrete floors would accelerate their discharge. This is no longer a problem as modern battery cases, made of polypropylene or hard rubber, are sealed against external leakage, which causes the discharge. However, the top of the battery must be kept clean and dry. Temperature stratification within large batteries could accelerate the self-discharge if the battery is sitting on a cold floor in a warm room or is installed in a submarine.

Provided the batteries are maintained in a fully charged status, batteries can be stored in temperatures as low as -25°F without freezing.

You should replace the battery if one or more of the following conditions occur:

- If there is a .05 (sometimes expressed as 50 “points”) or more difference in the specific gravity reading between the highest and lowest cells of a flooded battery after charge. This means the flooded battery you are testing has a weak or dead cell(s).

- If the battery will not recharge to a 75% or more state-of-charge level. You may notice your charger “timing out” when it was never used to when the battery was new.

- In an automotive battery with a built-in hydrometer that still does not indicate “good” after charge, the battery should be replaced (usually, the hydrometer will show green or blue, representing 65% state-of-charge or better if the battery is good).

- If a digital voltmeter indicates 0 volts on a battery that you know has been properly charged, you have a broken connector, or an open or short-circuited cell, you should replace the battery.

- If a digital voltmeter indicates 10.45 to 10.65 volts on a battery you know has been properly charged, the battery probably has a shorted or dead cell.

- If the battery is fully charged, you can test the capacity of the battery by applying a known load and measuring the time it takes to discharge the battery to 1.75 volts per cell (5.25 volts for a 6-volt battery – 10.5 volts for a 12-volt).

- If the battery fails to deliver at least 50% of its rated capacity - at the applied load - before reaching 1.75vpc, it should be replaced.

Note: Different types of batteries use test procedures that allow different end-of-life criteria.

For example:

Battery Council International BCIS section 6 Rev. DEC02 states that the measurement of the end-of-life cycle performance of a battery is defined as the point at which the battery will not deliver at least 50% of the manufacturer's rated capacity when discharged at the 2-hour rate. A golf cart battery would not be determined to be at its end of life until it could maintain at least 5.25 volts during a 40-minute discharge at 75 amps.

Depending on your application, batteries tested and proven to perform above 50% of their original capacity may not meet your operational needs even though they pass the industry good/bad test standard.

Discover thinks that in most commercial applications where productivity is critical, batteries that do not reach 60%-70% of original capacity should be replaced. If the battery passes the load test, recharge it as soon as possible to restore it to peak performance and prevent lead sulfation. Always consider the temperature when making your evaluation, and make sure that the batteries have been adequately charged before testing.

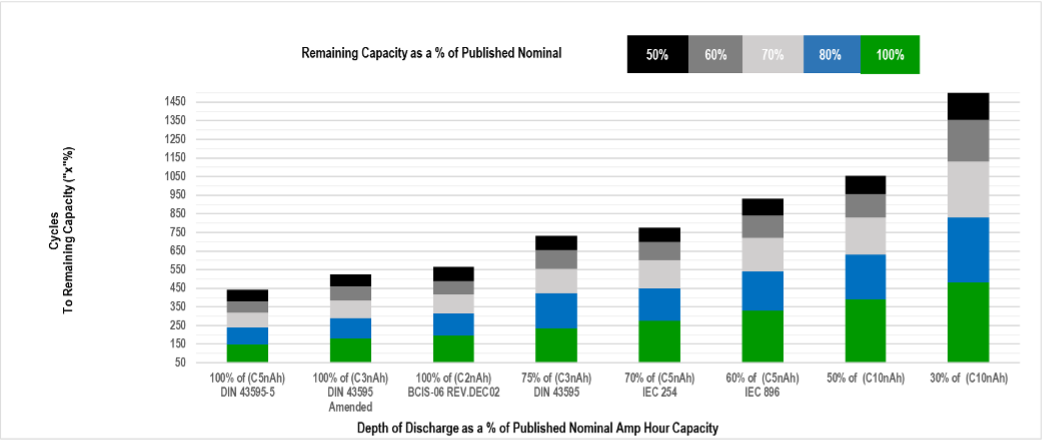

Figure 6 illustrates eight different Industry Cycle Life Test Standards with Remaining Capacities.

Figure 6 – Cycle Life Testing Standards at various Rates and to various remaining capacities

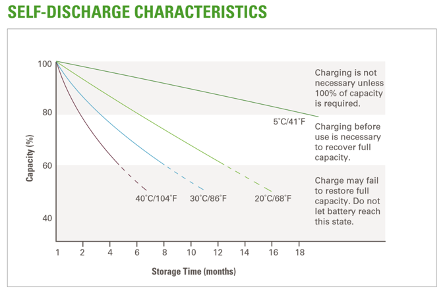

AGM and GEL batteries will have a self-discharge or internal electrochemical “leakage” of between 1% and 15% per month, depending on storage temperature.

This internal or self-discharge rate will cause the battery to become sulphated and fully discharged over time. High temperatures accelerate the process so that a battery stored at 86°F (30°C) will self-discharge twice as fast as one stored at 68°F (20° C). Discover AGM or GEL batteries will naturally discharge at approximately:

- 1%-2% per month when stored at 8°C/46°F

- 3%-4%% per month when stored at 20°C/68°F

- 5%-6% per month when stored at 30°C/86°F

- 10%-12% per month when stored at 40°C/104°F

By comparison, a quality flooded Deep Cycle battery will have a self-discharge rate at least two times greater than AGM or GEL batteries.

- Check and charge, if required, your Deep Cycle AGM or GEL batteries every 2 – 3 months.

- Check and charge, if required, your Deep Cycle wet Flooded batteries every 2 – 4 weeks.

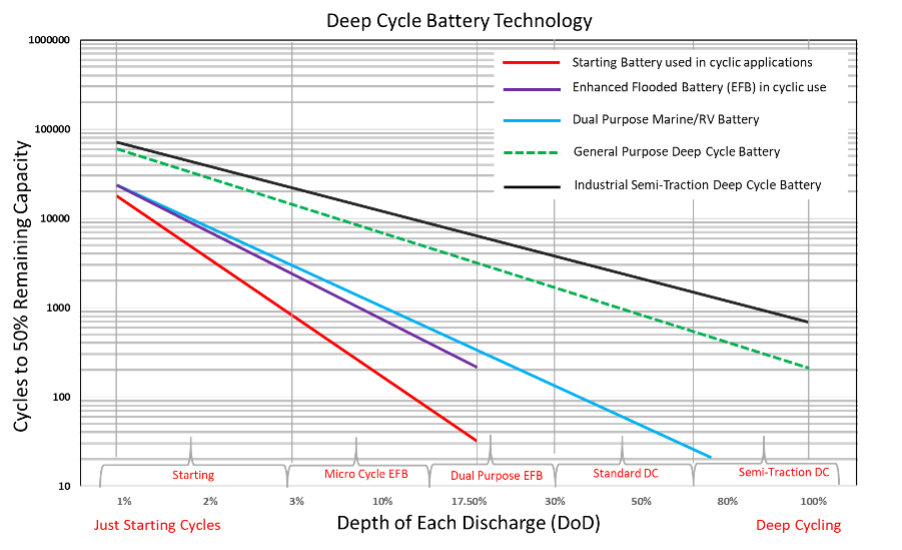

How long a battery will last in terms of its usable life depends entirely on the following:

- how often the battery is discharged and charged

- how fast or at what rate it is discharged and charged

- to what depth it is discharged (DOD) each time

- how well or properly it is recharged after each discharge, and,

- is it the right battery technology for the job it is being asked to do

When designing your system, the battery (battery bank) must be appropriately sized, given the job it will be required to do. Sizing that assumes a maximum of 50% DOD is preferable. Make sure that the system has proper low-voltage protection against over-discharge and that the charge source is capable of adequately charging the battery. A battery used regularly in deep discharge service should be matched with a charge source that can charge the battery in ideally no more than 10 hours giving the battery time to rest before being put back into service.

YES, and before anyone starts to complain, we are aware that many OEM equipment producers do not provide chargers that can charge the battery banks in 10 hours. No matter the battery's design life or what type of warranty is provided with the battery by the manufacturer, a battery is only capable of providing “X” amount of total capacity (i.e. 100AH battery x 150 cycles = 15000 AH total capacity). If the battery bank is undersized for the job it is being asked to do, it will fail sooner than the system design life you wanted to have. There is no substitute for proper system sizing.

This is the typical warranty and small print provided by some of the world’s premier manufacturers, and you can see loud and clear that a 4-year warranty means nothing if the battery is cycled out before the four years is up:

XXXXXXXX Products Inc. (“Manufacturer”) warrants its XXXXXXX batteries (hereafter referred to as “Battery”) to be free of defects in material and workmanship for the following Applicable Warranty Periods:

- Two years for Auxiliary Power Unit (APU) and other non-engine start cycling applications

- Two years for power sports applications

- Three years for commercial, industrial, marine and automotive applications in non-BCI sizes.

- Four years for an engine starting application for XXXX, XXXX, and all BCI sizes

The warranty does not cover a Battery reaching its expected end of life, which may occur before the warranty periods stated above. Depending on the application, a Battery can reach its expected end of life before the end of the warranty period. A Battery can deliver only a fixed number of usable amp-hours over its lifetime and is considered to have reached its expected end of life if the application uses up all of these amp-hours, regardless of the time the Battery has been in service. Therefore, the Manufacturer reserves the right to deny a warranty claim if it determines the Battery to be at its expected end of life, even if the claim is lodged within the applicable warranty period.