Calculating Cost to Own:

Estimate the cost of materials used when servicing the battery as the manufacturer recommends. For comparison, it is reasonable to use just $1.70 each time for distilled water, cleaning and neutralizing agents and ignore the other variable costs. Multiply this amount by the years the manufacturer says the battery will last in the application. Multiply the result by the number of times the manufacturer says the battery should be serviced per year to achieve the published life expectancy. Our experience shows that most manufacturers will recommend your service flooded batteries at least once a month. Two of the “World's” leading manufacturers and sellers of Flooded, GELL and AGM Deep Cycle batteries state the following on their websites;

"Flooded batteries need water. More importantly, watering must be done at the right time and in the right amount or the battery’s performance and longevity suffers. Water should always be added after fully charging the battery. Before charging, there should be enough water to cover the plates.”

“Batteries should be watered after charging unless plates are exposed before charging. If exposed, plates should be covered by approximately 1/8" of acid. Check acid level after charge. The acid level should be kept 1/4" below the bottom of the fill well in the cell cover. Water used to replenish batteries should be distilled or treated not to exceed 200 T.D.S. (total dissolved solids...parts per million). Particular care should be taken to avoid metallic contamination (iron).”

“As batteries age, their maintenance requirements change. This means longer charging time and/or a higher finish rate (higher amperage at the end of the charge). Usually, older batteries need to be watered more often. And their capacity decreases. Periodic battery testing is an important preventative maintenance procedure. Hydrometer readings of each cell (fully charged) indicate balance and true charge level. An imbalance could mean the need for equalizing, which is often a sign of improper charging or a bad cell. Voltage checks (open circuit, charged and discharged) can locate a bad or weak battery. Load testing will pick out a bad battery when other methods fail. A weak battery will cause premature failure of companion batteries.”

This would suggest that the world’s leading manufacturers of flooded Deep Cycle batteries recommend that service is required, particularly as the battery ages, BEFORE and AFTER every charge/discharge cycle. In some cases, they suggest that failing to do so will void the warranty.

If you cycle the battery two times per week, the battery will last approximately three years following the manufacturer's recommended service procedures. This means your per battery service material costs will be at least $1.70 x 12 services per year x 3 years = $61.20. If you service as the manufacturers suggest, it will be as much as $1.70 x 104 services per year x 3 years = $530.40.

Our experience shows that for a battery to last three years when being cycled two times per week, it needs to be serviced at least once every four cycles or bi-monthly. $1.70 x 3 years x 26 services = $132.60 per battery.

Every user of deep cycle batteries is familiar with dried out “rotten egg” smelling batteries, the result of NOT maintaining a proper service schedule over the battery's life.

NOTE: when asked, more than 80% of equipment managers could not produce or describe a “battery service schedule” - for equipment under their supervision that uses cycling batteries.

In our opinion, if you were to match a quality flooded battery against a Discover Semi Traction EV Dry Cell AGM or GEL battery of the same size and AH rating for use in the same application, you would find the total cost of ownership to be higher for the flooded battery option.

Discover Semi Traction EV Dry Cell AGM or GEL batteries require less service, and as a result, with proper charging methods, Discover batteries will out-value flooded batteries. It is more likely that the standards of service for the flooded batteries will not be met in the real world. Therefore, it will not meet the manufacturer's required levels to achieve maximum life.

Additionally, when considering flooded versus Dry Cell AGM or GEL, one must also consider other inconveniences and/or costs associated with servicing, working with or having sensitive equipment around flooded batteries. These would include, but are not limited to:

- damaged and/or special clothing

- battery compartment repairs

- air quality problems

- workers compensation claims

- occupational health issues

- hazardous materials handling requirements

- shipping restrictions

- damage to service areas from acid and corrosive by-product spills

We feel the more competitive and demanding the channel (jobber/installer/large user/rental equipment), the more compelling and feasible the switch to Discover Semi Traction EV Dry Cell AGM or GEL batteries becomes. The larger the bank of batteries used, the more significant costs associated with service become and the more compelling and feasible the switch to Discover batteries becomes.

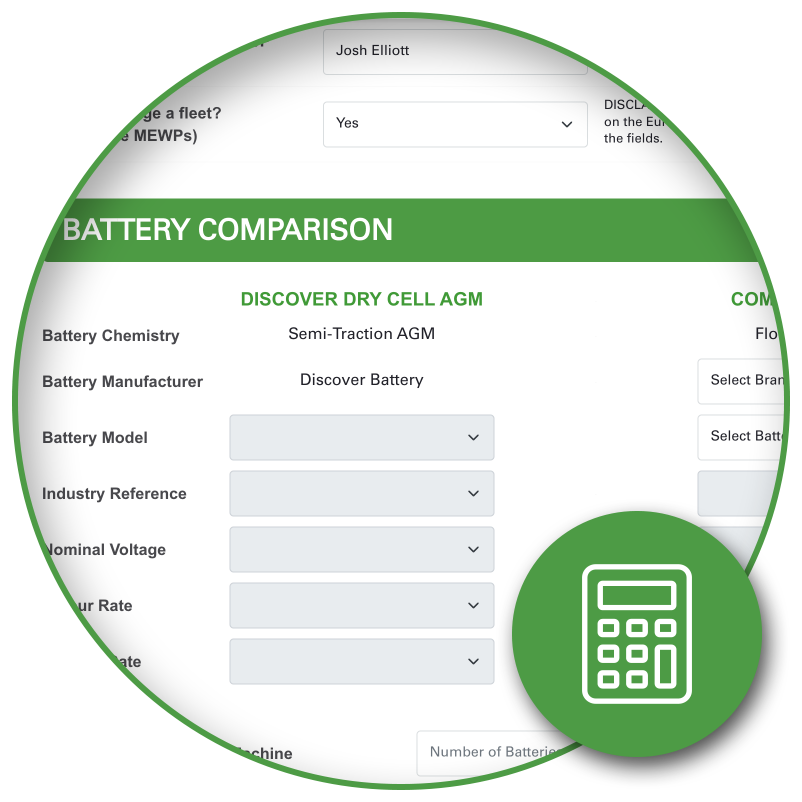

Check out our Mobile Elevating Work Platform TCO (Total Cost of ownership) Calculator.

Discover’s Mobile Elevating Work Platform (MEWP) Calculator is a tool for rental fleet companies and service providers that compares the capital and operating expenditures of MEWP when using Discover’s DRY CELL AGM Batteries versus flooded battery technology.